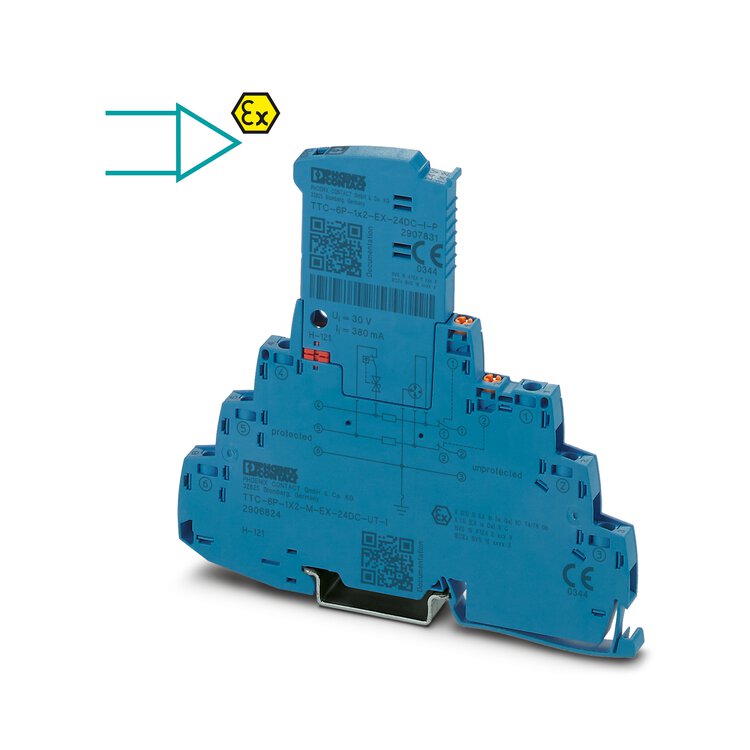

Explosive atmospheres repeatedly arise in the chemical and petrochemical industries due to industrial processes. They are caused, for example, by gases, fumes, or vapors. Explosive atmospheres can also occur, however, in mills, silos, and sugar and fodder factories due to the dust present there.

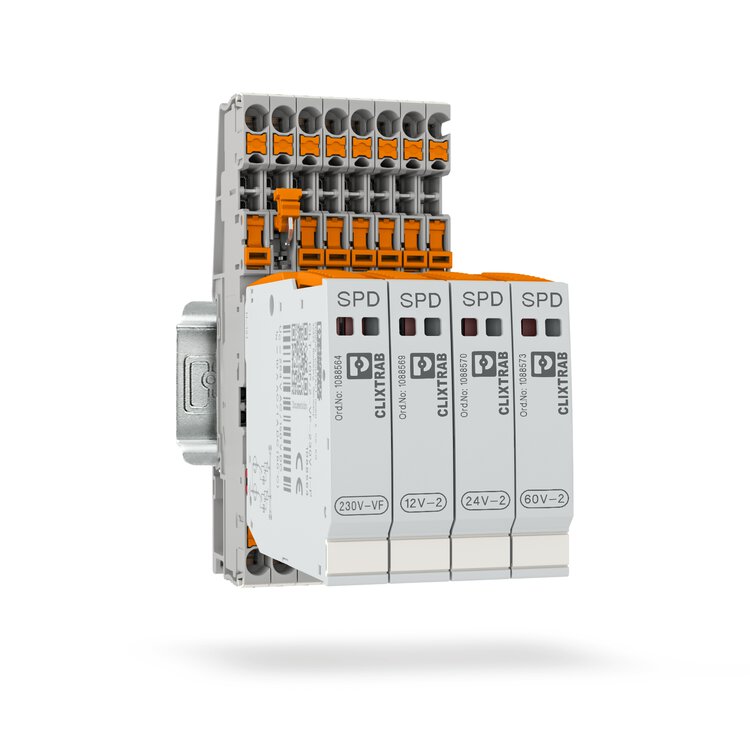

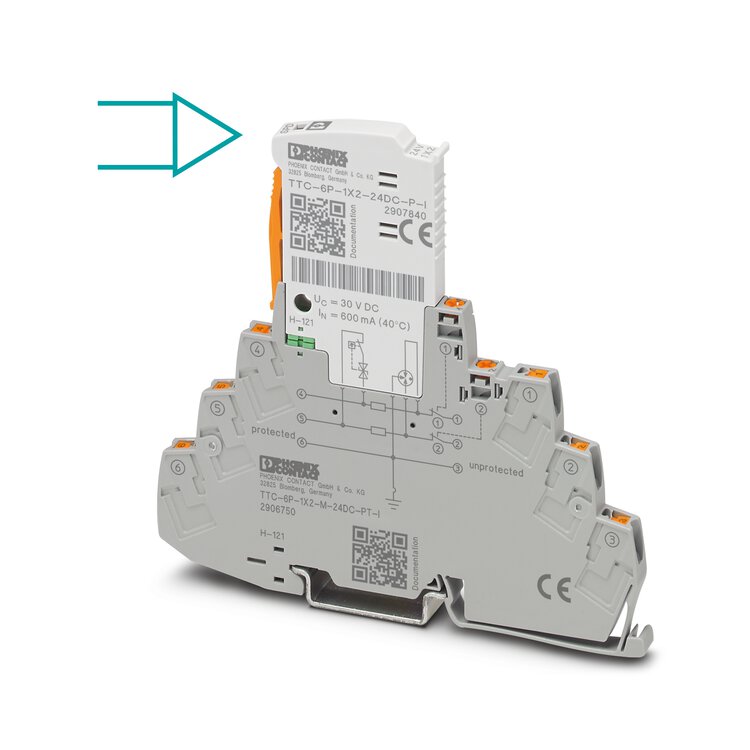

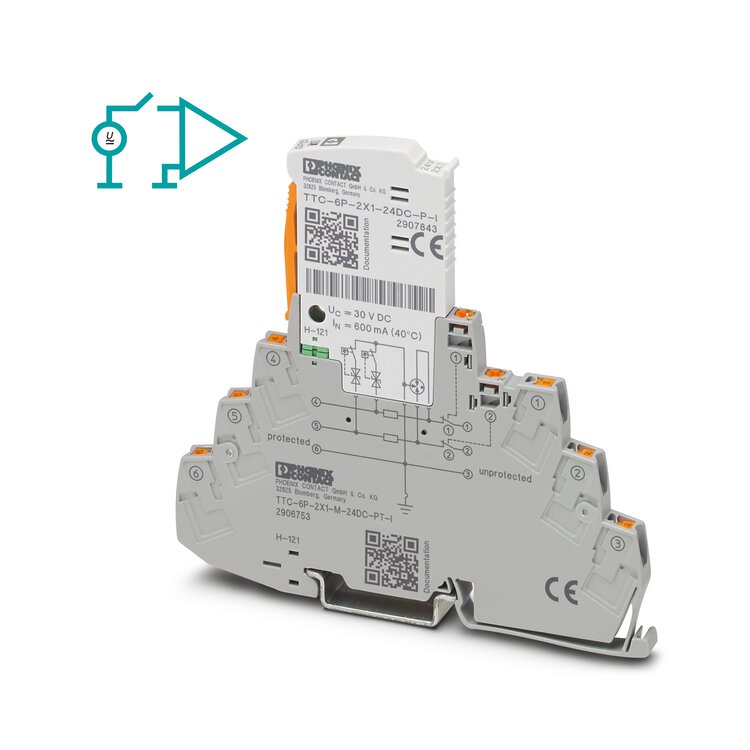

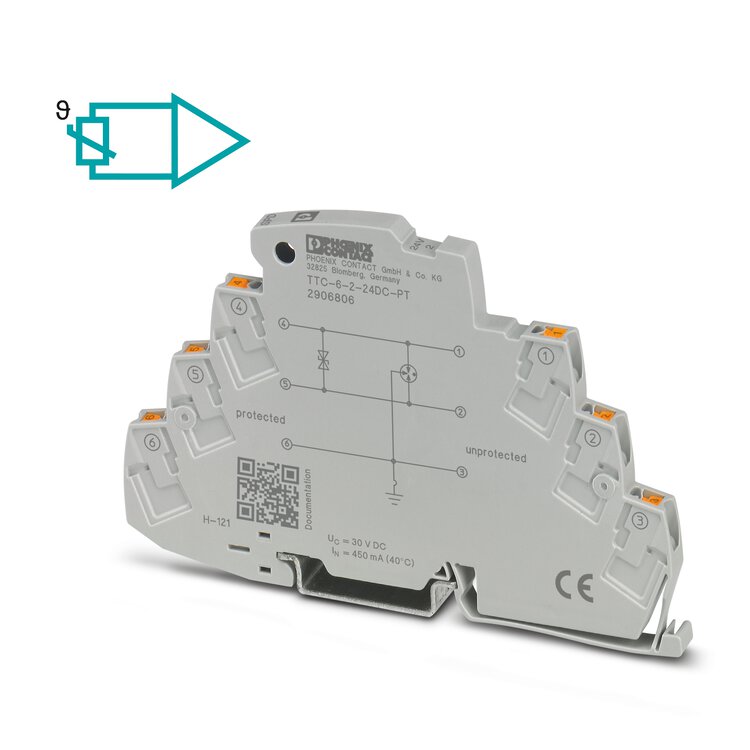

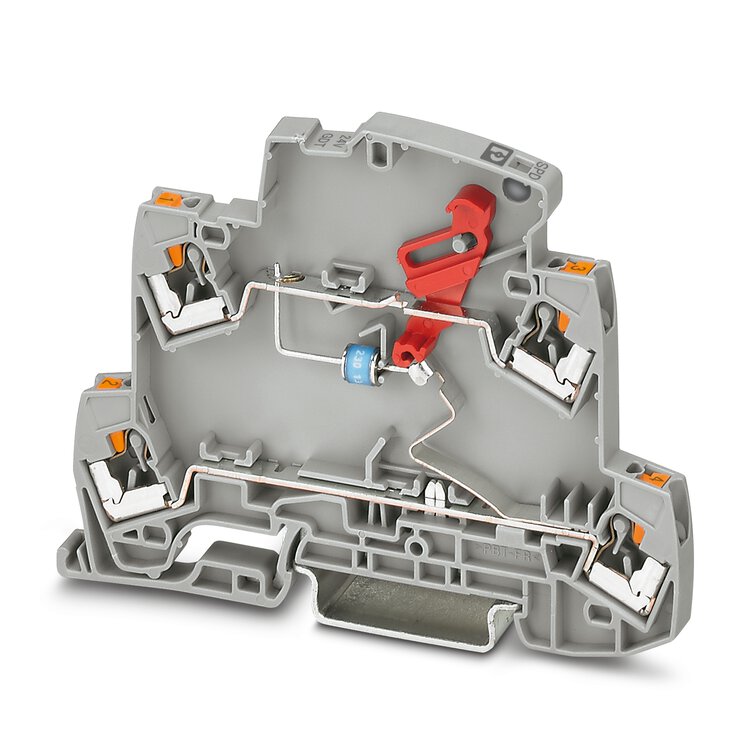

The surge protective devices for the Ex area are subject to specific conditions. The items therefore meet the specific requirements for intrinsic safety protection. Since all surge protective devices are assigned to the “Ex ia” category for intrinsically safe circuits, they provide maximum safety. In this category, the equipment must not be capable of igniting, even in the event of two independent faults.

It can be installed in Ex zone 1, Ex zone 2, or in the non-Ex area. The connected signals can be forwarded up to Ex zone 0. Some items also meet the requirements of pressure-tight encapsulation protection. Approvals are granted in accordance with ATEX and IECEx.