PLCnext Technology is the ecosystem for industrial automation consisting of open hardware, modular engineering software, a global community, and a digital software marketplace.

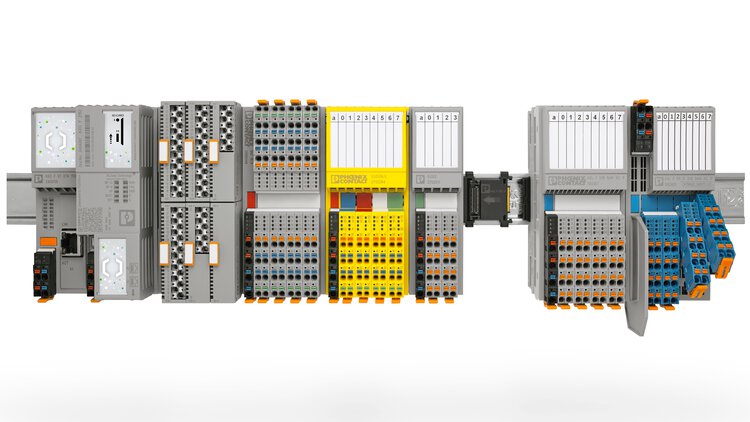

Digitalization and globalization are placing new demands on industrial automation. The precisely-tailored design of the open automation system is just as important as flexible, modular expansion.

In addition to standard PLC programming in accordance with IEC 61131-3, parallel programming and the combination of programming languages such as C/C++, C#, and MATLAB® Simulink® in real time is also possible with PLCnext Control.

Accelerate your application development process with the free basic version of PLCnext Engineer.

Or use your familiar programming environment – you decide!

Through simple cloud integration, the option to use open source software, and the constantly growing expertise of the PLCnext Community, you thus benefit from new forms of collaboration. The resulting solutions apps, software modules, runtime systems, and function extensions are available in the PLCnext Store and ensure enormous time and cost savings when creating applications.

This makes PLCnext Technology the ideal ecosystem for your modern automation challenge.