Ασφάλεια χειριστών

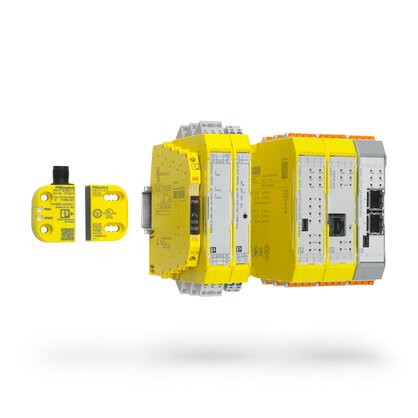

You can reliably implement safety functions in machines and systems using safety relay modules.

They monitor signals from emergency stop buttons, light grids, and safety door switches, and initiate a safe state where necessary.

The PSR product range comprises safety relays with fixed or configurable safety functions, zero-speed and over-speed safety relays, and safe coupling relays.